About Us

Pursue high quality with high standards

K-LITE Industrial started with a simple dream in 2004 and has gone through ups and downs!Today, K-LITE Industrial still retains its original intention and is dedicated to developing, producing and creating high-end lamp retro-reflector safety products.

Step by step, it continues to innovate and grow, and has become today's first-choice high-quality enterprise in the lamp reflector profession.

The company has passed ISO9001 quality management certification, and its product quality has passed China's national compulsory certification CCC, China's national voluntary certification CQC, EU certification ECE, and American SAE DOT various professional standards. It is also the first batch in China to complete China's national mandatory retroreflectors. Certified 3C enterprise.

Professional, innovative, pragmatic

In the hearts of people at K-LITE, it is well understood that continuous innovation driven by a strong platform of independent research and development capabilities is the only way to meet market demands, lead the market, and create miracles.

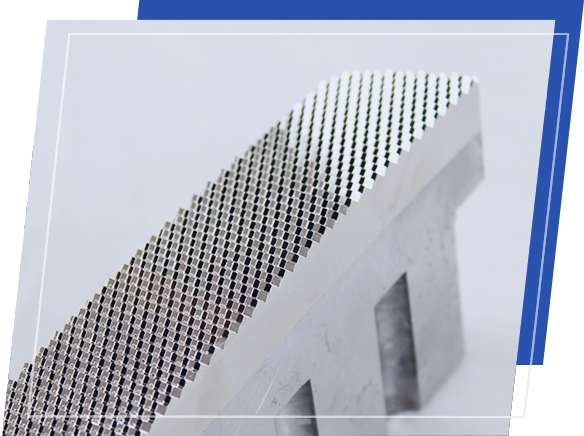

Untill now, we have obtained multiple technology patents and certified products of China,and we have undertaken thousands of retroreflector mold cores for our customers. Our main products include free-form surfaces and irregular shapes with micro-facets, applied to: motor vehicles, electric vehicles, bicycles, road safety studs, delineators, and triangular warning signs for roadblocks.

Our current retroreflector electroforming manufacturing capacity is 200 sets per year, with 50 electroforming machines.

.png)

Caring for the environment and protecting life are the unchanging corporate purposes of our company.

Our electroforming model factory is the first one amfd the only one in China obtained certification from China MEE。

As for our long technological evolution process, we started by referring to technology from Canada, purchasing and using key production from the United States, and investing heavily in the acquisition of Tianda Tianguang Reflection, formerly a subsidiary of Tianjin University, which possesses key grinding technology and optical design technology. coupled with the company's continuous research and improvement, after twenty years of hard work, we have finally achieved what we can today。

From grinding PIN (electroforming needle), optical design, multi-stage electroforming and precision machining ,we got whole process know-how ,is one of the few in the industry. This also ensures the stability of the technology and the quality of the electroformed mold cores produced, allowing our electroformed mold cores to be used in the manufacture of car lights and reflectors. When it comes to the final product, the quality can be guaranteed by complete self-control, fulfilling our basic responsibility of K-LITE Industrial to protect the life safety of users.

Win-win

A good company and good products need good customers and friends. Thank you to our customers and friends who have stayed together through thick and thin. Let us join hands with Keguang to light up life, never forget our original intention, and work together for a win-win situation!