Technology

- Home

- Technology

- Retro reflector

- Retroreflector

Retroreflectors

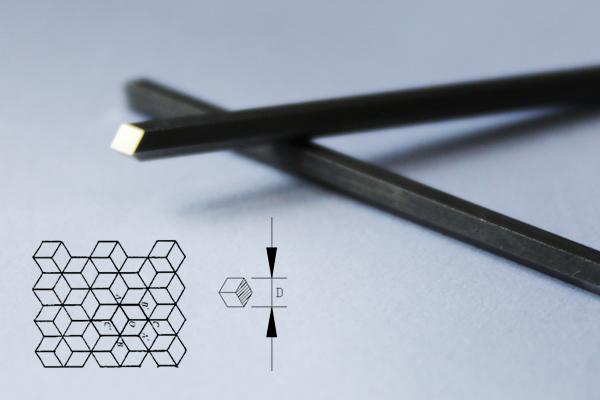

Reflex reflector is composed of a plurality of reflex reflective optical element arrays. reflex eflective optical units mainly include microbeads and cubic pyramid prisms.

The reflex reflector used in automobile is composed of many cube corner prism arrays,plastic Optical injection molding.

The so-called cube pyramid prism,that is areflection prism with three reflection surfaces at right angles to each other,also know as a three sides right angle cone prism, a corner prism,acorner cone prism,etc.

Regulatory Standards

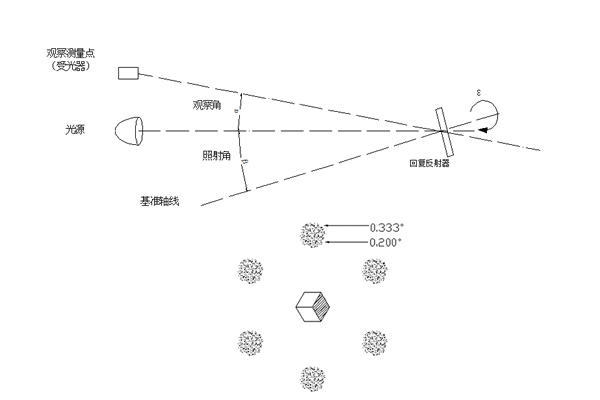

When testing retroreflectors, only one of the six groups of light rays is within the effective detection area.

Common angles: 0.200° and 0.333°

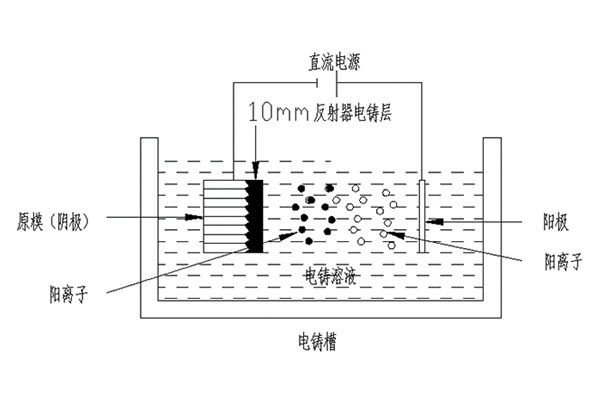

Retroreflector Mold Core Manufacturing Process

In the RR jig master mold, electroforming technology is used to perform electroplating and then separation to produce (or replicate) nickel products. The basic principle is the same as electroplating. However, while electroplating aims for a metal coating firmly bonded to the substrate for protection and decoration, the electroformed layer needs to be separated from the core mold and is much thicker than an electroplated layer. Generally, the thickness of an electroformed layer is 0.01 to 0.05 mm per hour. The conventional electroforming thickness for reflectors is thicker than 10 mm.

Reflector Mold Core Production Workshop

Production equipment workshop

Electroforming equipment workshop

Reflector Mold Core Production and Processing Equipment

CNC

Slow wire EDM

Medium wire EDM

Optometry laboratory equipment